| Yibi Factory |

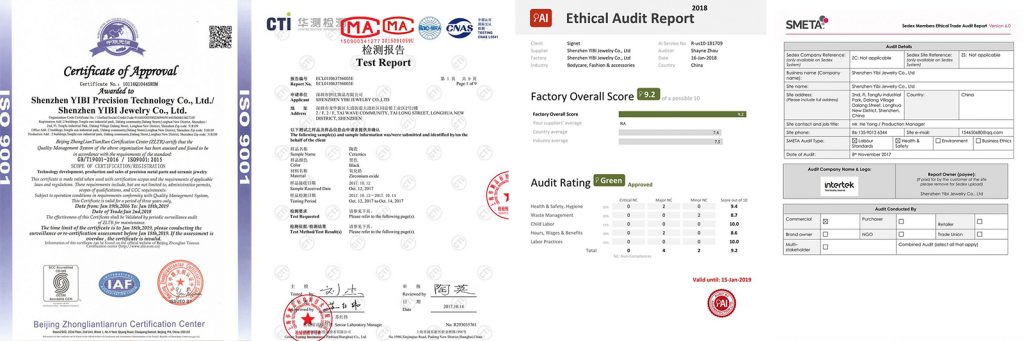

Yibi is now a national high-tech enterprise and has obtained more than 30 certifications. It has passed ISO 9001 quality management system certification, SA8000, and FAMA certification. The company has also received recognition and certification through collaborations with three high-end luxury group. Additionally, we have obtained certifications in Sedex, GRS, RCS, SGS, and others.

Currently, Yibi covers an area of more than 16,000 square meters. With skilled artisans and engineers working together, we guarantee the precision and quality of each product. Yibi currently employs 800 highly trained professionals, ensuring we have the capacity and expertise to handle large-scale and complex projects.

Our manufacturing plants are equipped with the latest machinery and technology, ensuring we can meet the demands of high-end jewelry production, including EDM, MIM, CIM, CNC, lathes, polishing, engraving, plating, stamping, 3D printing, and other large-scale machinery.

The factory is capable of handling key processes such as mold making, injection molding, degreasing, grinding, polishing, logo lasering, laser welding, assembly, ultrasonic cleaning, PVD coating, and more, with a fully integrated production line. Each product undergoes thorough quality control at each stage of the process. Once the product is completed, lab testers conduct a series of tests in our own laboratory to ensure the highest quality.

In short, Yibi Jewelry provides a one-stop service to our customers. We consistently embrace new technologies, trends, and concepts with open arms. By leveraging talent and technology, combined with scientific management, we create value for customers, build a promising future for employees, and contribute to society.