What is the PVD?

Physical vapor deposition (PVD) describes a variety of vacuum deposition methods which can be used to produce thin films and coatings. PVD uses physical deposition to deposit a coating on the surface. The most common PVD processes are sputtering and evaporation. PVD is carried out in a closed ultra-low pressure vessel, which is physical process.

How does the PVD works?

Working Concept

PVD processes are carried out under vacuum conditions. The process involved four steps:

1.Evaporation

During this stage, a target, consisting of the material to be deposited is bombarded by a high energy source such as a beam of electrons or ions. This dislodges atoms from the surface of the target, “vaporising” them.

2.Transportation

This process simply consists of the movement of “vaporised” atoms from the target to the substrate to be coated and will generally be a straight line affair.

3.Reaction

In some cases coatings will consist of metal oxides, nitrides, carbides and other such materials.

In these cases, the target will consist of the metal.

The atoms of metal will then react with the appropriate gas during the transport stage.

For the above examples, the reactive gases may be oxygen, nitrogen and methane.

In instances where the coating consists of the target material alone, this step would not be part of the process.

4.Deposition

This is the process of coating build up on the substrate surface.

Depending on the actual process, some reactions between target materials and the reactive gases may also take place at the substrate surface simultaneously with the deposition process.

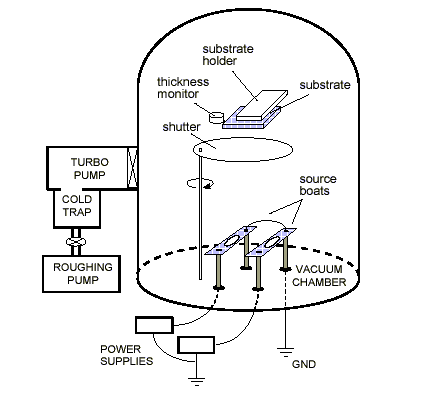

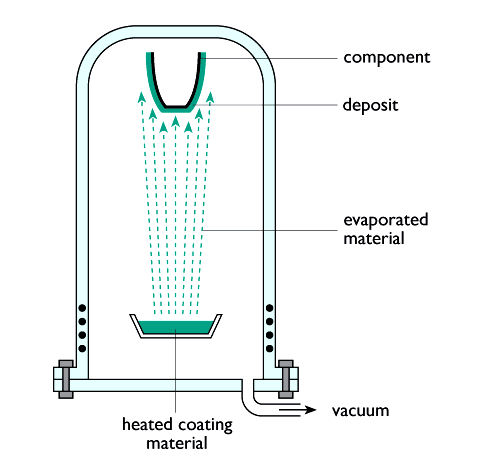

Picture shows a schematic diagram of the principles behind one common PVD method.

The component that is to be coated is placed in a vacuum chamber. The coating material is evaporated by intense heat from, for example, a tungsten filament.

An alternative method is to evaporate the coating material by a complex ion bombardment technique.

The coating is then formed by atoms of the coating material being deposited onto the surface of the component being treated.

Importance of PVD Coatings

PVD coatings are deposited for numerous reasons. Some of the main ones are:

Comparison to other deposition techniques

Yibi purchased another batch of PVD vacuum coating machines this year, which has made a huge improvement in the PVD coating process. These machines make the project delivery faster and the product plating quality better. Now they are in normal operation and provide consumers with the best service and greater protection.

New PVD vacuum plating machines show

YIBI Plating Color Chard